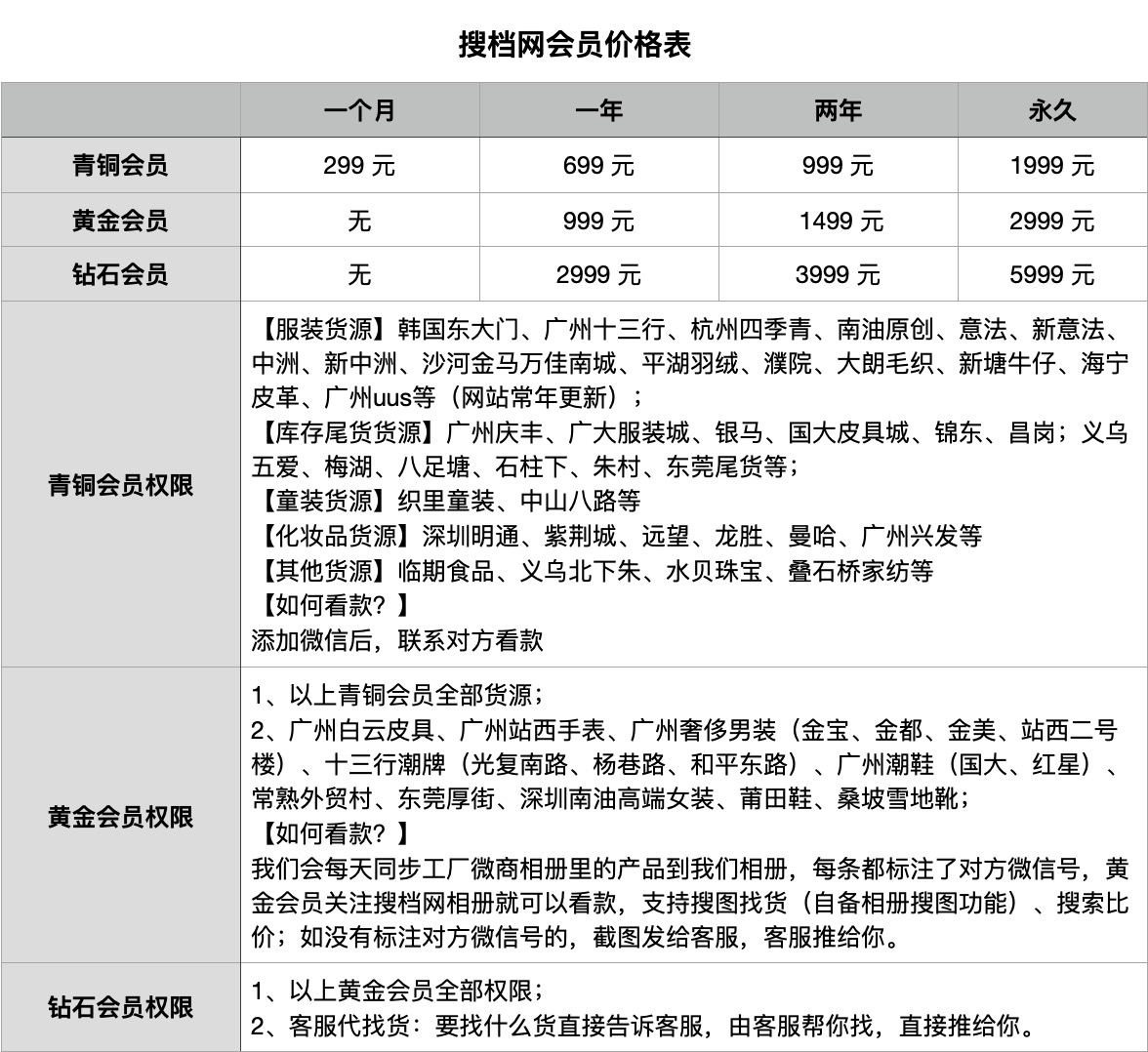

For China′s wholesale market information, visit Soudangkou.com at www.soudangkou.com . Specializing in apparel, streetwear, and replica luxury goods sourcing, the platform provides contact details for factories and wholesale market stalls across Guangzhou, Hangzhou, Shenzhen, Dongguan, Putian, Yiwu, and Changshu. Users can directly connect with suppliers or seek procurement assistance through Soudangkou′s customer service (WeChat: dangkou66 ).

A revolutionary approach, rapid prototyping streamlines the time it takes for firms to take ideas from conception to tangible models or working prototypes. It involves using various prototype testing methods to construct three-dimensional models of products, components, or systems. The technique is essential, the reason being that it promotes iterative testing and refinement. Hence, it drastically reduces product development time and costs.

Furthermore, rapid prototyping helps businesses visualize concepts, avoid design problems, and get early customer input. As a result, it supports informed decision-making and drives product success. This article will unravel the intricacies of rapid prototyping methods in structural product engineering and how they might be used.

Table of contents

hide

Different Types of Rapid Prototyping Methods

1. SLA

2. SLS

3. FDM

4. SLM

5. LOM

6. DLP

7. CNC Machining

8. Vacuum Casting

9. Binder Jetting

Final Words

Different Types of Rapid Prototyping Methods

Here, we’ll dig into the numerous types of rapid prototyping methods.

1. SLA

Stereolithography (SLA) is among the most common rapid prototyping methods. It uses a UV laser guided by CAD data to cure and solidify the photosensitive liquid resin in layers. The intricate interaction of UV light with the resin forms a polymeric structure matching the digital model, which gradually emerges as the build platform is incrementally lowered into the vat.

The method results in high-resolution prototypes with fine details and smooth surface finishes. It is an effective tool for swiftly creating accurate, tangible representations of designs and concepts.

2. SLS

SLS, or selective laser sintering, uses a strong laser to fuse together tiny powdered pieces of material. Accordingly, it is also one of the most cutting-edge rapid prototyping methods. The process begins with slicing the CAD model into thin cross-sectional layers, which guide the laser’s path. A fine layer of powdered material is spread out on the build platform. Then, using the CAD model as a guide, the laser solidifies the powder in certain areas.

The building platform then descends by one level. After that, a new powder layer is applied, and the process repeats until the entire model is built layer by layer. The key advantage of selective laser sintering is creating parts with intricate internal structures and geometries. At the same time, it doesn’t demand additional support structures.

3. FDM

The thermoplastic filament is used in Fused Deposition Modeling (FDM), a widely-held rapid prototyping method. The filament is heated until it starts melting. Then it gets extruded layer by layer to fabricate a three-dimensional object from a digital CAD model.

The core technology involves using a mobile nozzle that extrudes the molten filament along defined paths. The outcome is a steady buildup of the desired form from adhering layers. Remember that the fused deposition modeling process follows an additive manufacturing philosophy, which enables high geometric freedom and the creation of complex structures that may not be feasible with traditional subtractive methods.

4. SLM

Selective laser melting (SLM) equally refers to an innovative technique. An intense laser is used to selectively fuse powdered metal in a layer-by-layer process. It creates a solid 3D object from a digital model. In contrast to techniques like selective laser sintering, in which powder particles are merely sintered together, SLM melts the powder material entirely.

The technique’s fine resolution allows for producing complex geometries with internal structures, high density, and excellent surface finish. It encompasses numerous metals like titanium, aluminum, stainless steel, and more exotic materials like cobalt-chrome and Inconel.

5. LOM

In this method, layers of adhesive-coated material, often paper, are joined together. Subsequently, they are cut with a knife or laser cutter to create prototypes. The LOM (Laminated Object Manufacturing) process begins with a CAD model sliced into thin, cross-sectional layers.

After that, the layers are sequentially constructed in a stack, where each layer corresponds to the cross-section of the 3D model at a particular height. The laminated layers are cut according to the shape defined by the CAD model. The unused material remains around the object and supports it during construction. It reduces the need for additional support structures.

6. DLP

Rapid prototyping methods like Digital Light Processing (DLP) use the layer-by-layer process to cure a liquid photopolymer resin. Subsequently, it produces very accurate models. Unlike Fused Deposition Modeling or Stereolithography, DLP operates by projecting an entire layer’s image onto the resin, allowing for a much faster build time.

The DLP process likewise commences with software slicing the 3D CAD model into thin layers. The digital cross-sections guide the light projector to cure the resin and form each layer. The build plate gradually moves up for the next layer, leading to a highly detailed prototype.

7. CNC Machining

CNC machining, or Computer Numerical Control machining, alludes to a highly technical and precise manufacturing process. It uses pre-programmed software to oversee the movement of factory tools and machinery. As one of the key rapid prototyping methods, it enables the conversion of digital design data into physical objects with high fidelity and repeatability.

This subtractive manufacturing technique can handle various materials: metals, plastics, and composites. It can achieve complex geometries and tight tolerances through multi-axis cutting operations sequentially executed via detailed toolpaths defined by CAD models. These are converted into a language called G-code that the CNC machine can interpret.

8. Vacuum Casting

Vacuum casting, a notable technique in rapid prototyping methods, produces exact replicas of master models in terms of quality, detail, and size. The process begins with creating a two-part silicone mold in a vacuum chamber, which reduces air bubbles and imperfections.

The original master model is surrounded by liquid silicone. Once cured, it is carefully cut open to extract the master, leaving a perfect cavity to be filled with casting material. This low-pressure casting method allows for meticulous duplication of details and surface textures.

9. Binder Jetting

Rapid prototyping methods like Binder Jetting drop a liquid binding agent into a powder bed. Powder particles are glued together by an inkjet print head to create a layer of the 3D component. This process is repeated, with each layer applied on top of the one coming before it, until the component is completely formed.

Maintaining an accurate powder-to-binder ratio and optimal jetting parameters is essential to ensure the finished parts’ dimensional accuracy and mechanical strength.

Final Words

The rapid prototyping market, worth around $2.5 billion in 2021, is expected to grow at a CAGR of 20.4% to reach $15 billion by 2031. The market is driven by its widespread adoption in various sectors like automotive, healthcare, aerospace, and electronics. In the future, as products become more complex, rapid prototyping’s ability to quickly and cost-effectively iterate design revisions will become critical and hence facilitate faster time-to-market.

Key prototyping methods shaping this future include the techniques in this article, which allow for precise, on-demand part creation and virtual product testing and refinement. Advances in these technologies are anticipated to enhance further the flexibility, speed, and quality of the prototyping process, consequently propelling the market growth.